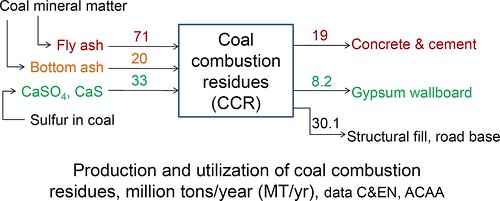

The 2/23 edition of C&EN had an article (subscription required) on problems associated with disposing ash generated from coal-fired power plants. Here is a link to a publication from The National Academies Press on managing coal combustion residues, which has some interesting additional background information. The article advocated that calcium sulfate/sulfide-containing wastes from flue gas desulfurization (FGD) be kept separate from the coal ash waste. Proper means of disposal in a dry, lined landfill is required to prevent leaching of the heavy metals to the environment. The scale of the problem/opportunity is shown in the above figure. What are some of the additional uses of ash, particularly fly ash and what are the challenges to their utilization?

The cement industry is the single largest consumer of fly ash. This works, because blending flyash into clinker not only is beneficial economically, but also enhances durability of the concrete. However, low-NOx regulations resulted lower firing temperatures, which result in unburnt carbon in fly ash. Cement manufacturers could co-fire high-carbon fly ash in their kilns as a component of the raw kiln feed, provided that certain precautions are taken. Additionally, research at Penn State & the University of Nottingham has focused on using the unburnt carbons in the fly ash to capture mercury emissions from power plants. Fly ash can also be used to make bricks, The Greenest Brick Company being an example.

Environmental implications of coal combustion residue handling and disposal are critical, because of the potential for heavy metal contamination and other health issues. Therefore, enhanced utilization of coal combustion residues should be one component of environmentally responsible utilization of coal.

The cement industry is the single largest consumer of fly ash. This works, because blending flyash into clinker not only is beneficial economically, but also enhances durability of the concrete. However, low-NOx regulations resulted lower firing temperatures, which result in unburnt carbon in fly ash. Cement manufacturers could co-fire high-carbon fly ash in their kilns as a component of the raw kiln feed, provided that certain precautions are taken. Additionally, research at Penn State & the University of Nottingham has focused on using the unburnt carbons in the fly ash to capture mercury emissions from power plants. Fly ash can also be used to make bricks, The Greenest Brick Company being an example.

Environmental implications of coal combustion residue handling and disposal are critical, because of the potential for heavy metal contamination and other health issues. Therefore, enhanced utilization of coal combustion residues should be one component of environmentally responsible utilization of coal.

No comments:

Post a Comment